Good morning, after having deeply analyzed the characteristics and the operation of the machining center, today we are going to illustrate the operation and the composition of the lathe. This machine is probably the most important machine, certainly the widespread, of all the machine tools.

In the following articles, we will have a deeper look at the technological evolution of this machine over the time. We will show also the functioning of the modern CNC lathes and their different configurations. But first, today it is important to understand how the lathe works.

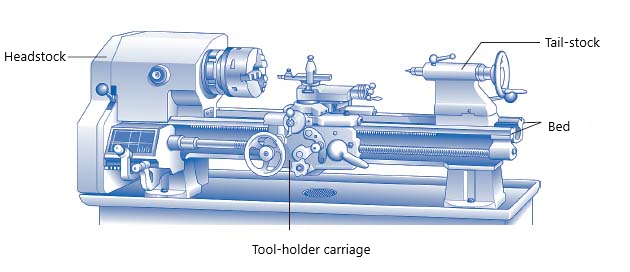

So let’s start with the description of the traditional lathe: the conventional parallel lathe.

The conventional parallel lathe

The conventional parallel lathe is, without any doubt, the most used machines for chip removal in the world and consequently the most used in the mechanical industry.

By using the lathe it is possible to make a wide variety of machining operations using various tools that can be easily managed. The main

The main production that a parallel lathe can carry out is the realization of revolutionary solids, it means all the objects with circular shape section. In particular, by working with the lathe, it is possible to realize cylindrical and conical surface, boring, holes, threading, spherical turning and shaped turning. The main characteristic of the lathe, which diversifies it from the milling machine, is the movement of the workpiece.

The motion of the workpiece will be a rotating motion that is moved in a circular way by the spindle, the main shaft of the machine.

The workpiece can be mounted in two ways:

- Embossed, clamped by the chuck which is screwed around the spindle

- between the points, by using a using a support mounted on a mobile device called tailstock and in line along the sliding guides

When you want to buy a lathe, it is important to establish two fundamental parameters related to the type of machining that will be necessary to carry out with the machine.

If you need some tips concerning buying a used machine, please read this article by clicking on the green button below

The two fundamental parameters are:

- The maximum turning length which is identified by the maximum distance between centers

- The turning diameter (you can identify this parameter by the height of the centers and by the presence of the traversing slide)

The headstock of the lathe is composed by the spindle and by all other mechanical devices necessary to convert the rotary motion generated by an electrical motor into the rotary motion of the spindle and the straight movement of slides or guides.

One of the characteristics of the parallel lathe is the feeding motion of the tool that generally consists of a movement parallel to the z-axis or the spindle axis.

In planning turning work, such as the faceting, the movement of the tool is perpendicular to the axis of the lathe. Only in this case, it is referred to traversal feeding.

Among the main component, we find the tool-holder carriage composed by a slider for longitudinal displacements (along with the Z-axis) and a slider for transverse displacements. The carriage also has a plate rotating around a vertical axis to allow the orientation of tools mounted on the tool holder slider.

The tail-stock is based at the same height of Z axis, but sometimes it is higher for roughing operation, lower for the finishing ones.

The movement of the carriage is carried out manually or mechanically through a mechanical gear system that transfers the spindle motion to the carriage. In such cases, the speed will be related to the rotation speed of the workpiece by the use of interchangeable wheels.

To sum up, the conventional parallel lathe is composed by the following main component:

- Bed: Provides a heavy rigid frame on which all the main components are mounted.

- Headstock: mounted near the spindle. Using a chuck, it bears with the workpiece

- Tail-stock: it fit the length of the workpiece.

- Toot-holder carriage

Today we have described the conventional parallel lathe. In future articles in our blog, we will describe in detail all the components and the applications of CNC lathes.

If you are interested in CNC multitasking lathe, vertical turret lathes, or facing lathes, do not hesitate to visit our catalogue.

If you want more information about the machine in the first picture, click here: Used Hyundai KIA SKT 21 LMS Lathe with live tooling [machine sold]